HOMY STEEL HANGARS

Homy introduced «Steel Hangars» solution to supply steel hangars to offer a complete range of products for the base camps.

Manufactured with light steel profiles (according to Homy’s light steel frame philosophy), Homy’s hangars can reach a height of 10 Mt and cover spans of doorway until 22m.

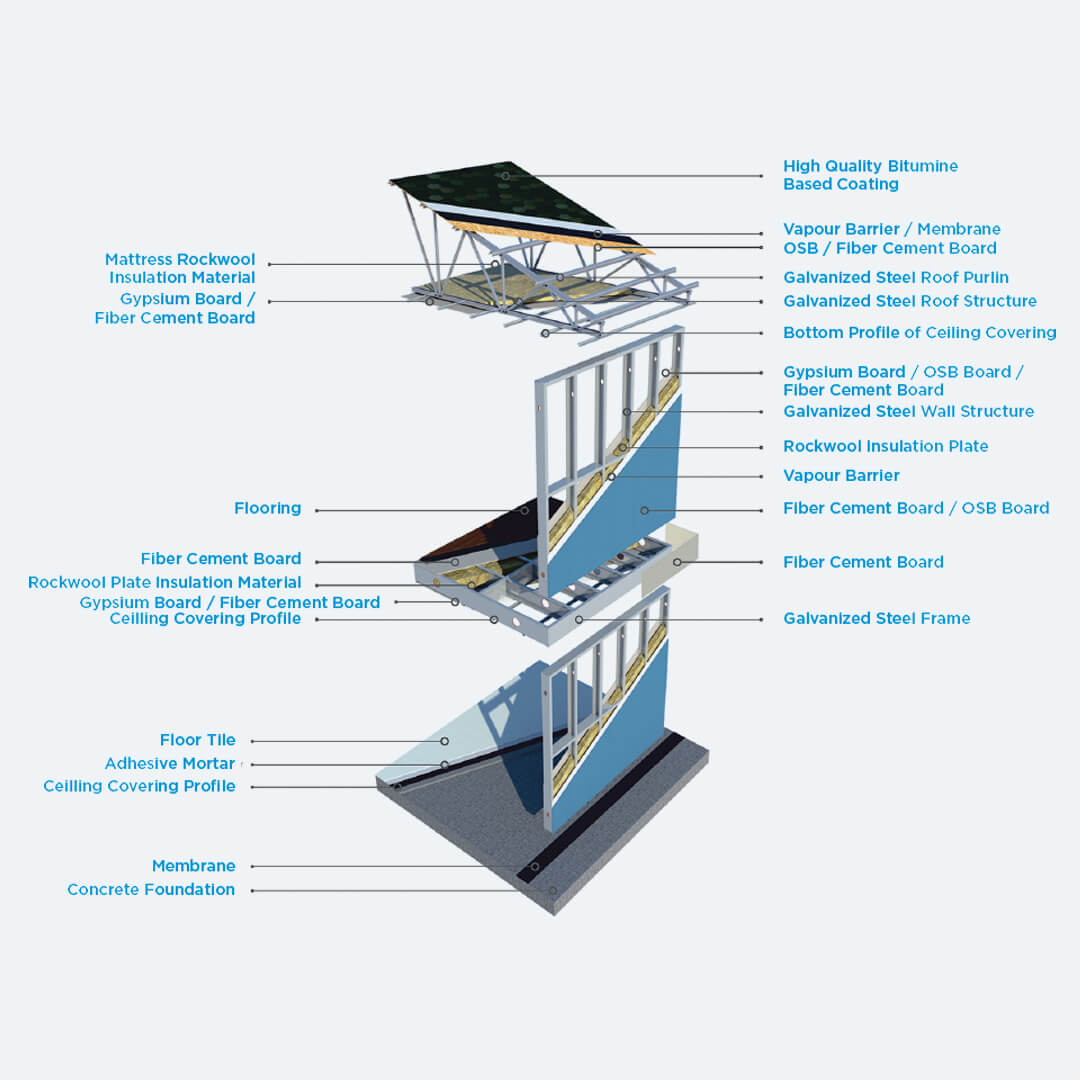

Standard proposal includes walls in galvanized sheet, but on request Homy can offer different solutions with insulated walls and roofs. The materials and thicknesses choose will be studied by Homy team according to the destination site.

The profiles of Homy hangars are hot-dip galvanized in order to assure high constant and long lasting performances, no matter which are the weather conditions, reducing in this way the maintenance costs.

When required, the Homy Steel Hangars system can be naturally combined with the traditional carpentry, permitting to reach increased sizes and load capacity.